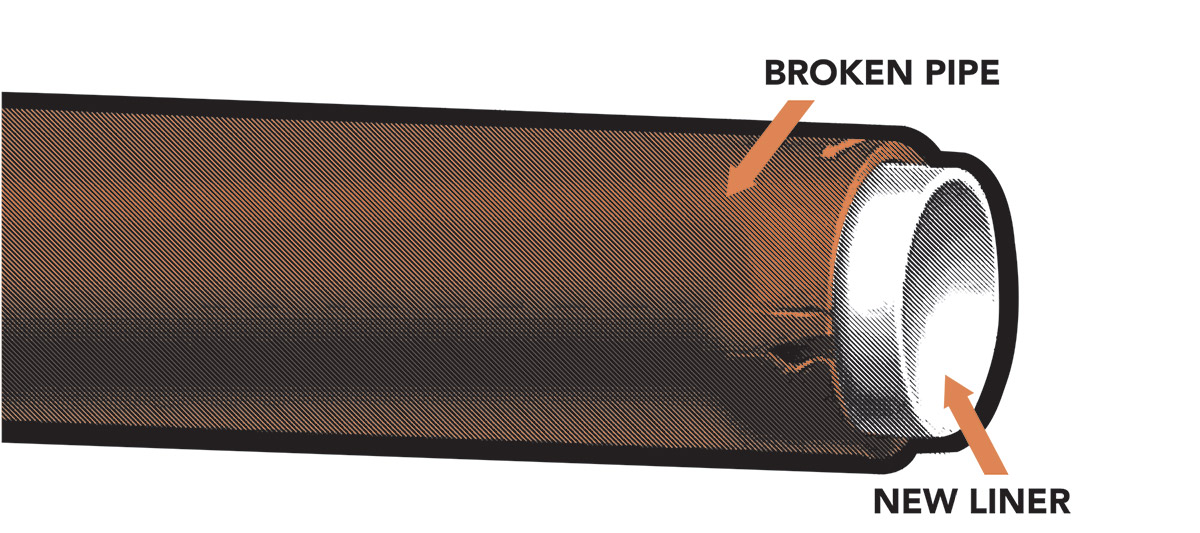

Cured-in-place-pipe (CIPP) is a trenchless technology used to repair existing pipelines. With the capability to restore pipes ranging from 3” to 110” in diameter, CIPP is a jointless, seamless pipe-within-a-pipe. CIPP can effectively reduce infiltration and leaks in pipeline systems without digging. Read more about how CIPP works.

To understand how CIPP works on a damaged pipe, a resin-saturated felt tube made of polyester, fiberglass cloth, or any number of other materials suitable for resin saturation, is inverted or pulled into the damaged pipe. Access to the damaged pipe is gained via manhole or from another existing access point. The cured tube is then positioned by visually monitoring it via video camera. The point repair is then pressed firmly against the inner wall of the damaged pipeline using air pressure. When it is in place, it is then cured with an epoxy mixture that forms a thin, protective wall around the damaged pipeline.

The process begins by using a high-velocity jetter to clear all foreign material and debris out of the host pipeline. Next, a video camera is used to determine the exact location and condition of the damaged pipeline. When this has been determined, an epoxy mixture is saturated into a mat constructed of fiberglass and felt. This mat is wrapped onto what is known as a bladder and is then inserted into the pipeline, and then brought right to the exact location of damage. Using air pressure, the bladder is inflated to the proper level to couple the repair to the pipe. After the proper curing time, usually two to three hours, the bladder is deflated and removed. This ends the point repair process.

CIPP is usually performed from an upstream manhole or access point. It is possible to install a liner from a downstream access point, upstream to a blind end; however, this carries the highest risk of all CIPP installation methods.

The pressure necessary for inversion can be generated using pressure vessels, scaffolds, or a Chip unit (a small piece of semi-conducting material, usually silicone, on which an integrated circuit is embedded). To cure the resin and form a tight-fitting, jointless, and corrosion-resistant replacement pipe, hot water, UV light, or steam is used.

Since all resins shrink and it is impossible to bond to a sewer that has fats, oils, and grease, an annular space exists between the new CIPP liner and the host pipe. The annular space exists in all installations, but some are larger than others. To prevent water from tracking in the annular space and re-entering the waste stream, the most effective method is to use a hydrophilic (water swelling) material placed at the ends of the host pipe and the lateral connection. The rehabilitated pipe is then inspected by closed-circuit television (CCTV).

Now you have the basics on what cured-in-place-pipe is, and how it works! If your business needs a repair anywhere on their pipeline, give CIPP in Dallas a call – we’ll help you see if CIPP is the right method for you. Click here to contact us!